Pot Still Distillation

Pot still distillation is a way of separating water from alcohol. It is often used to produce high-flavor spirits. However, it is not a particularly efficient process. The final product usually contains alcohol between 40 and 60%. This is because it is less energy-efficient than other types of stills. Although the process can yield high quality spirits, it is also labor-intensive.

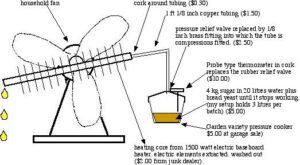

There are four basic areas of a Pot Stills. They are the main chamber, the lyne arm, the coiled condenser, and the collection vessel. Each of these areas has a significant influence on the character of the spirit produced.

The main chamber is a large spherical shape that contains the mash. The mash is boiled and the resulting vapors rise up into the lyne arm. These vapors then travel into the coiled condenser. After being cooled by cold water, the alcoholic vapor is pumped into the collection vessel.

Pot Still Distillation – How A Pot Still Works

Indirect heating with hot steam is another common method of pot still distillation. These stills look slightly different on the inside than those with direct heating. Those with indirect heating are less subject to mechanical wear.

Pot stills can be constructed from copper or stainless steel. Copper is a good conductor of heat and is useful for removing sulfur from the final spirit. Stainless steel is usually used in column stills. A typical column still consists of several chambers that are stacked on top of each other. Both of these stills can be made in a variety of designs.

Traditionally, pot distillers used direct heat sources. During this period, most pot stills were heated with coal. Today, most pot stills are indirectly heated by using natural gas or oil. But some pot distillers continue to use direct heat.

Pot stills are used for a wide variety of purposes. For instance, they are used to make rum, whiskey, schnapps, and even flavorings. Many pot stills have been in use for many years. Though they may not be the most energy-efficient distillation system, they are highly versatile. With the right components, they can yield high-quality whiskies. If you’re visiting a craft distillery, take the time to study the different parts of the pot still.

The shape of the still has a huge effect on the evaporation of the vapors. This is because the shape creates a larger surface area on which the vapors interact with the copper. As a result, some vapors will condense before others. Because this happens, a portion of the vapors will be discarded and some will remain.

Another factor that influences the distillation process is the size of the pot still. The taller the still, the more delicate the spirit will be. Conversely, a squat still allows more lower alcohols to be distilled. Stills that have both a high and low level of height can be very effective at producing higher proof spirits.

The lyne arm connects the neck of the pot still to the coiled condenser. This lyne is connected to the upper part of the spherical lid via a bend.